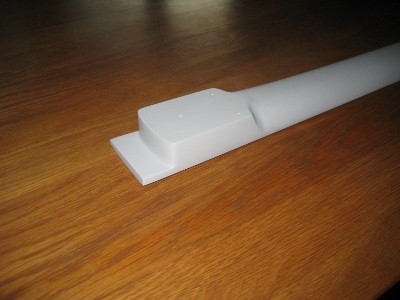

As advertised previously, I have also created a new MDF mould for the neck. To learn working with carbon fiber, I decided to make it a bolt-on neck mould. Then I realized that this is a perfect component for the Ergonomic Guitar System, so I made the dimensions the “standard” dimensions, which meet the body at the 21st fret. With this, it will be possible to purchase a neck and a bridge to get a truly ergonomic instrument from almost any bolt-on instrument.

I started by laminating three 19 mm pieces of MDF:

and then I butchered a (yes, you guessed it) an ironing board to create a routing jig for the neck twist:

Once I had completed the passes with the router, I ended up with this:

and with plenty more work:

The plan is that tomorrow, I will start to create the negative mould (out of fiberglass and epoxi) that I will then do the final carbon fiber neck in. I visited a custom carbon fiber shop yesterday for research purposes, which was interesting. Will report soon.