As you know, I am building several EGS guitars in parallel in order to explore material choices and what impact they have on sound and playability. I have opted to make my design bolt-on and using a standard Fender Strat neck pocket. This allowed me to get only a slightly custom neck made by Moses Graphite, knowing that it would fit. This will also allow me to make several necks to swap around on the different builds.

As hinted previously, I am doing an experiment with carbon fiber. The idea is to be able to make a neck that is stiff enough to allow it to be hollowed out to some extent, to make it lighter.

In the image above, you can see the type of carbon fiber that I guess most people associate it with, which is a bi-directional weave, in the lower left. In the top right, you have a uni-directional weave. I am after stability in only one direction, so this is what I chose.

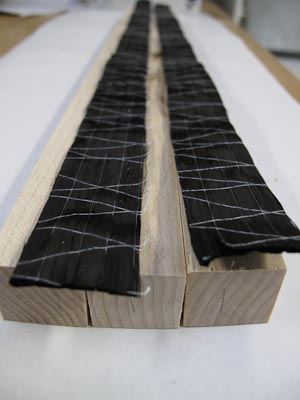

The neck blank consists of a flatsawn piece of maple that I cut in three pieces that will be stacked.

I cover the pieces in lots of epoxi (a resin made especially for lamination with carbon fiber, that hardens into a glass-like consistency), place the carbon fiber mat, whet it with epoxi, cover the next piece of wood with epoxi and then stack it on top.

I press the pieces together only slightly, but the threads that hold the weave of the carbon fiber together ensure that some distance is kept and that not all epoxi is squeezed out.

This then bakes at 60 degrees centigrade for 24 hours in a very rudimentary oven.

The results are very encouraging and will be the topic of a follow-up article in the near future.

That’s a brilliant idea laminating that way. Will you keep the carbon intact when hollowing out the neck. Btw, do you expect the hollow neck to do anything to the sound? And, will it have a truss rod?

I am eager to know, so I am looking forward to the update.

/Alex

Hi Alex,

yes, I will keep the CF intact. And, I will have an adjustable truss rod, since I believe different players will want different action, and different string gaugues and climates will require it (assuming it is not 100% stiff…) The plan is to use a Martin-style box rod, which is made of aluminum and should be lighter than a regular double-action rod.

If anything, I think hollowing out the neck will make it respond faster. Time will tell… My current trapezoidal neck is quite hollow due to the CF tube (inner diam 12 mm) and works very well.

/Ola