It’s been brewing for a long time, but I am thrilled to finally bring to you the EGS Pro Tremolo. This is based on a completely friction less needle bearing design – needles offering a much larger area of transfer of energy than both ball bearings and knife edges, and thereby better sonic properties. It is also much more durable than a knife edge, practically impossible to wear out. As all EGS hardware, it is extremely light-weight, and built on the proven EGS combined bridge/tuner/tailpieces, with complete tuning stability. The dimensions make it possible to use existing Floyd-Rose routing templates, and the dimensions are slightly larger than the footprint of an original Floyd-Rose, so that you can retrofit an EGS Pro tremolo into an existing Floyd-Rose recess. In addition, the EGS Pro tremolo is lefty friendly – simply mount the tremolo arm on the other side.

But I’m saving the best for last: the Dual Action. You can mount the tremolo in two different ways for two completely different feels and actions. What this means to you as a luthier is that you can stock the same tremolo for many different types of musicians. For you as a musician, you can tailor the behavior to suit your playing style.

Here is a short demonstration video:

The EGS Pro tremolo will be offered in 6-, 7-, and 8-string versions (Dual Action is available only on 6-string). Formal launch is expected at NAMM in Anaheim, CA on 13th of January, 2011!

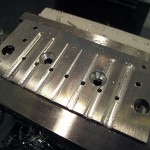

It’s been an exciting weekend in the shop. This is what happened:

Do you have a rough figure for what these are going to sell at? I’m very interested in using one for a project I have lined up.

Hi Sam,

I expect them to be the same as the previous version (to be confirmed…)

I look forward to hearing from you.

I’m very excited over developing this. The high cost and non-availability of a consistent quality supply of my knife edges was holding me back in the tremolo development.

Best regards,

Ola

That’s great to hear! I truly think you have brilliant and innovative design going for you along with clearly superior quality.

Thanks again!

All the best,

Sam.

These do look very interesting indeed. Do you reckon they’d fit in most floyd top routes? I don’t mind routing deeper or whatever but it’s difficult to cleanly route a top route on an already painted guitar.

How would it be mounted? Using similar bushes pressed into the guitar like a regular floyd?

What kind of string height could be achieved with it?

@Owen: you would need to enlarge the route compared to a Floyd-Rose, since they are wider on the arm side and mine are symmetrical from the guitar’s center-line. The front edge and bottom edge are the same, so you need to enlarge the rout on the rear and top side (on a right-hand mount). Just like you say, some finishes can be tricky to rout after-the-fact, but with masking tape and a sharp bit at high speed, it’s usually OK.

The prototypes put the intonation point about 17-19 mm off the guitar’s surface, so you would likely deepen the rout as well. You mount it with two screws on each side. Height adjustment is done individually per string (base plate has radius) and not for the entire tremolo.

Mr Strandberg, when you say string adjustment is done individually, then citing the baseplate radius ..do you mean the chosen radius of the baseplate should match the fingerboard’s radius once and for all? No raising or lowering the string height according to the different string gauge, tension, different neck radii etc?

Well at least there aren’t any adjustable threaded posts, that was one big mistake of the past for many trem designs.

Ok for needle bearings , same choice as Vigier’s modified floyd concerning only the bearings, but how much pressure can they stand before failing? If one wants to put some ultra-heavy string gauges as ’52 or ’56 lowest string gauge for example?

Are the bearings you chose pop-in mounted thus replaceable if they fail?

Are your baseplate and largest trem components (trem block, tuning tubes etc) in “non-magnetic” alloys?

@Xenon: thanks a lot for your very good questions. The radius of the base plate is intended to provide a baseline (16″ in the prototypes). Any other radius, as well as difference in action between treble and bass strings, can easily be accommodated by the individual height adjustment. The saddle inserts, on which the strings rest, are threaded with a very fine thread, and by turning them half a turn at a time, you can adjust the action.

As with all Strandberg designs, all wear-and-tear parts are replaceable. The bearings and pins can be popped out (the sharp bent end of the tremolo springs act as the tool to do it.) Having said that, your concern is valid. For the Dual Action parts, the dimensions are well within, but still close to, the documented maximum loads. For this reason, I am only offering this on the 6-string tremolos. 7- and 8-string tremolos will have a larger dimension bearing which will have a single mounting location.

All parts, except wear and tear parts, are 7075 aircraft grade aluminium which is non-magnetic. Any parts that can be worn or are under high stress are either stainless steel or hardened carbon steel.

Wow… like all of your work, this is a beautiful and elegant solution.

Have you given any thought to making the unit self-contained by using a torsion spring (or torsion bar) rather than a traditional Fender-style spring-and-claw arrangement? My preference is for thin bodies, and a spring cavity behind the pickups usually means the body has to be full depth.

Mr Strandberg: I checked for needle bearings, shell type with no inner ring like yours, inner diameter from 3-6 mm , outer diameter from 8-10mm : the companies try to impress with relatively high static load capacity values (like around 2000N) , but the fatigue load limit is quite low something between 150-300 N …I see what you mean when you say “still close to documented maximum load” !

What I really don’t understand is how ibanez zr models don’t shatter when I see the dimensions of their ball bearings : 4.5-5mm inner diam, 8.5-9mm outer diam, maybe 3-4 mm width, full stainless steel, deep groove, open . the values are impressively low, like static max load 250N and fatigue limit 11-12N (yes, only 11-12N !!).

How come they don’t break so often then? I see there are replacement bearings as well from Ibanez, but not many seem to have their bearings damaged (unless the damage is subtle to notice: flattened balls ? indented cases?)

@darren: thanks for your kind words, and congratulations on a beautiful line of guitars! Torsion springs are tricky in that there are very few standard sizes – they tend to be all custom (at least where I have looked) and I have such small volumes that it would be prohibitively expensive (I will accept suggestions if anyone knows of a supplier!). I have thought of a pressure spring arrangement like on the Steinberger tremolos, but opted for a Fender-style arrangement after all since most builders will have the routing templates already. We will see what the future holds…

@Xenon: I have a theory that perhaps bearings do deform, but that they perform sufficiently well regardless. Consider a typical tremolo action of +10/-5 degrees. A 1 mm cylinder will have a circumference of 3.14 mm. If you roll this cylinder 15 degrees around a shaft that is 4 mm, the required travel along this circumference will be roughly 0.5 mm. So, perhaps the range of travel is so small that any deformation is inconsequential? Bearings are dimensioned for 1000s of rpms, and in this case, a deformation would be disastrous. I will gladly accept input from someone with more experience on the subject.

It’s true these small bearings are intended for use on drill shafts and similar equipment, so in this use the high heat and revolutions would uniformize the defects in the bearing and untemper the rolling elements, grooving as well the internal race and melt the cage if under overload, but in tremolo use, as you say in 15 or maybe 20deg at the very most in terms of range and considering the room temp use as well as mechanical overload and very low speed (the highest speed would be when pulling the “fluttering” sound effect) I thought we’d have some additional surface hardening (like cold rolling, literally!!) and slight faceting of the rolling elements and a mild brinelling of the races.

What’s sure is that with trem use we’d never have untempering, rather surface over-hardening and cracking perhaps (if using 12-56 gauge for example being tuned in E on a 25 1/2″ scale ) after a certain prolonged time of use….

I’s still weird to have all the string pull pressure being applied on one or two rolling elements in rest position, leaving the other needles/balls relatively unused.

The interesting thing to do would be to see if with full ceramic bearings the ceramic balls would get crushed or if instead the additional stiffness would make them last longer(talking about ball type).

did you try any?

I noticed a second hand ZR2 trem had wobbly bearings when not mounted on the guitar: low tolerances or self adjusting ? self adjusting isn’t made in these small shapes unless custom made and they would be too expensive, so I’d say low tolerances + extensive whammy.

The bearing companies make “hobby” bearings for fishing reels, skates etc, they should start making some for specific use with trems why not one day! So people like you shouldn’t be obliged to use bearings made for drilling machines…

Darren mentioned springs…did you try the “noiseless” plastic covered springs for floyds? Are they that good for dampening unwanted spring oscillations ( “zings” ) and for a better return to rest position ?

I did try ceramic bearings earlier, but this was in an experiment where I simply replaced the knife edge with bearings and let the bearings rest against the regular tremolo posts. Mechanically, it worked just fine, but they did not sound as good as a knife edge. I am attributing this is to the loss of energy when transfering from base plate->shaft->bearing->post->bushing->wood.

With this new tremolo, the chain is base plate->shaft->bearing->housing->wood, eliminating one transfer point and using needle rollers instead of balls, thereby increasing the surface for the energy transfer.

I have not experimented with springs or any rest-position kits. However, I am pondering a locking solution (selectable one-way/two way lock) that would work with the existing tremolo blocks (more about this later I hope).

Hey, I just checked, just for the sake of comparing with your new design, the ZR from ibanez has 2 (!!) ball bearings per side (since one small ball bearing may simply fail in no time) , a total of 4. I wonder why they didn’t opt for a single needle as large as two ball units (no joke here) . It adds more friction to stick two bearings together, especially if you hammer them in to get a tight fit.

I see on your vid that the axis going inside the shell type needle bearing just slides in smoothly

Look at these pics, you clearly see 2 bearings per side.

http://static.keebali.com/jemsite.com/news/edge2003/

http://www.gear4music.com/media/20618/600/preview.jpg

I wonder what the cage holding the balls is made of: teflon, nylon or bronze, personally I think polymer cages in the bearings suck the high end of the tonal spectrum.

What’s your opinion on this?

there are 3 issues that should be adressed with your design:

-how to you intonate? I see we’re supposed to unscrew a tubular saddle but how to adjust while the string is under tension without a device similar to the official floyd rose “the key” ? http://www.prorockgear.com/theykey.aspx

It seems necessary to unstring to adjust intonation, re-screw to baseplate and re-string to check if the new intonation is ok, if not start again all over?

-the distance between the adjustable height saddle inserts and the part that holds the ball end is too important, divebombs and other exagerated whammy fx may displace the string and it wouldn’t “land” properly when retruning to rest position: I never tested your prototype, but it seems like it could happen.

@xenon: you are correct in your intonation thoughts and I will be developing a “key” like mechanism. For fixed bridges, this issue is not as pronounced since it is quicker to tune than a floating trem. The Floyd-Rose design is the optimal way to get around the dive-bombing issue, but does not really lend itself to a bridge mounted tuning system.

Regarding two ball-bearings vs. one roller, IBZ have probably made this choice for good reasons. It will allow the shaft to rotate around the post and still work – one bearing will take the axial force in one direction and one will take the opposite force created by the rotation. That whole term is a very well thought out design. One of my design goals is to keep things simple and modular, so I’m working within some constraints that they obviously don’t have.

Thanks for your excellent comments.

True, the IBZ ZR bearings work as one stabilizing the other more or less, but still the contact area between is too small, your needle bearings are better.

Why I talked about IBZ’s choice is because their bearing models are exactly those used in the fishing reel industry, so they were better off adapting their design to be retrofitted with bearings that would cost the least amount of money and produced in great numbers.

A trick similar to their despicable choice of pure zinc, zamac and other crappy zinc based alloys found on their low end trems. Saving a maximum of dough.

the question is, with a heavy trem user, wil there be some substantial axial load when raising the bar or will it be compensated in some way without resorting to angular or adjusting bearings?

Something else: I’ve been googlin’ around to see if some individual tubular saddles which tune more or less like some early steinberger designs were available from other brands: seems like you have a competitor with ABM-mueller.Com tuners (product codes: 3901 for bass, 3801 for guitar, page 8 of their catalog, saddles are said to be “bridges” for headless designs) , but I don’t approve their choice of chrome-plated brass.

I don’t approve also the fact that with Mueller’s design it is not feasible to intonate and change radically string gauge if they were to be screwed on your trem design for example (they placed the holes on the individual bridge while your placed the SLOT on the individual bridge for intonation with the hole in the baseplate instead ,your choice being wiser) .

The only good point would be the adjustable height system and the slightly reduced distance from where the ball end is attached to the adjustable height bridge small part (part which is larger and could catch the string after a divebomb). Still their height adjustment is reminiscent of the usual Fender saddle system, nothing original there.

I wonder if they took inspiration from your saddle-tuner design or not! If they did you can do it to them too huh !

I’ve been excited with your EGS tremolo for a few years.

But I have a concern of ‘retrofit’.

Do you have any plan to make the bridge retrofit to OFR stud or stud bushing??

I think that another design option of half-circle-shaped mounting metal piece for OFR mounting stud(or bushing) is possible.

Hi Amuck,

the goal of this new design was not to be a retrofit. Since the headless tuning system works best with some clearance behind it, it is advisable that you modify the rout regardless. The OFR trems are also asymmetric in shape whereas the EGS tremolos are symmetric, making them equally suited to leftys. So, there are a few challenges in maintaining compatibility.

Best,

Ola

Hi,

Does this tremolo allow for any up-pull like a Floyd Rose, or does it only go down in pitch?

Regards, Steve.

Hi Steve, it does allow pull-ups. You can find several demos on my YouTube channel http://www.youtube.com/user/olastrandberg

Hello!

Is this transposing trem?

How far it can pull strings up and down? Maj3? 4?

Thanks!=)

It is not transposing unfortunately. The original version has two points of action as in http://youtu.be/bHblk76fiI8, but the current production tremolos only have one.

Since it is not transposing, each string will give you a different range, but for example, you can pull the G string up to B.

Thanks for response!

Strandberg TransTrem is still in development? Or you dont work in this way right now?